Technical Information

Technical Information Power And Control Cables

Power And Control Cables Power Appendixes

Power Appendixes XLPE (Cross-liked Polyethylene)

XLPE (Cross-liked Polyethylene) PE Crosslinking Advantages

PE Crosslinking Advantages صفحه PE Crosslinking Advantages

PE Crosslinking Advantages

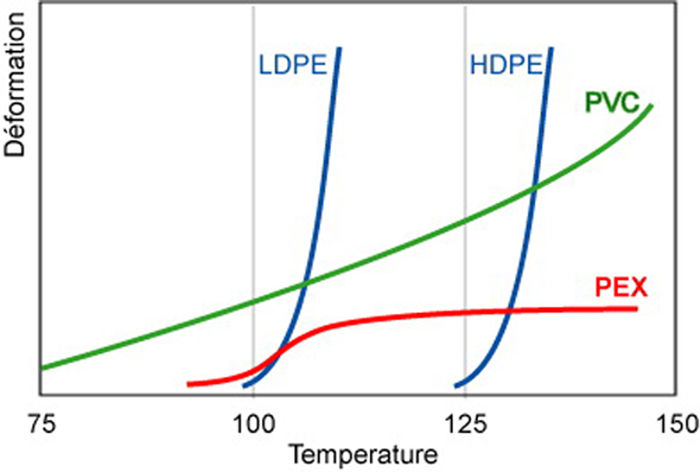

1) Increased Maximum Operating Temperatures

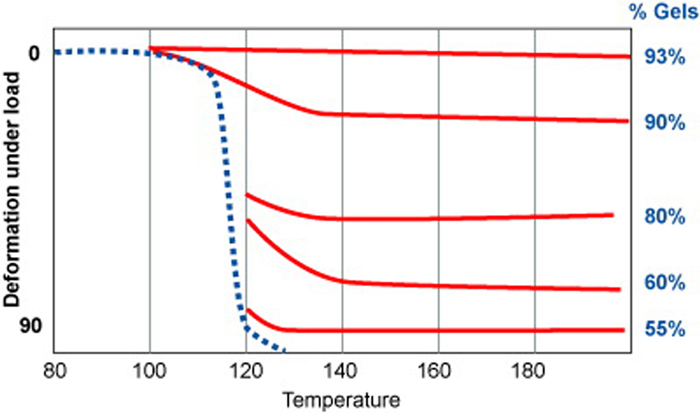

One key reason to Crosslink PE in applications such as Pipes or cables is to raise the thermal stability of the material under load. PEX continuous service temperature is around 100-120°C. Following figure compares thermo-mechanical deformation resistance versus temperature of various polymers.

The thermal-mechanical stability of PEX depends strongly on its degree of crosslinking (%gels).

This figure shows how % gel influences thermo-mechanical performances of PEX

2) Increased Chemical and Environmental Crack Resistance

In general, as the molecular weight of polyethylene increases, the environmental stress cracking resistance (ESCR) is improved. In some extend, PEX can be considered as an infinite molecular weight PE.

PEX exhibits superior ESCR and better slow crack growth resistance than standard HDPE .

|

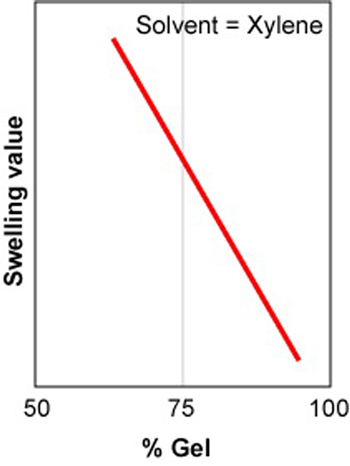

It is also well recognized that chemical resistance of polymers increases with the degree of crosslinking. This Figure shows how the degree of crosslinking influences the swelling value of PEX in a solvent such as Xylene. |

|